Corliss Steam Engine

Breathing new life into a battered old veteran

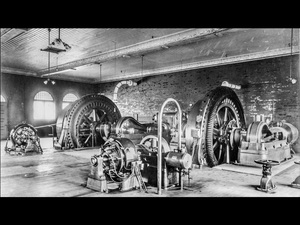

In 1902, after flooding had destroyed the original power plant, a new building was constructed on higher ground and initially fitted with two powerful Corliss steam engines. Note that the term "Corliss" did not define the manufacturer, but rather the style of engine defined by the semi-rotary valves and variable valve timing scheme patented in 1849 by George Henry Corliss. This type of valve gear in a steam engine offered the best thermal efficiency of any type of stationary steam engine until the refinement of the Unaflow steam engine and steam turbine in the 20th century. It was capable of delivering a continuous, uniform flow of rotary power in spite of sudden changes in the load that might be imposed on the engine. The smoothness of power delivery was very important, especially when generating electricity where the line frequency is totally dependent on the engine speed.

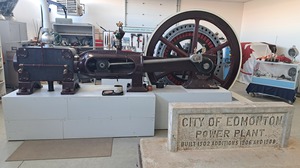

It only seemed fitting that the EPHF should have a Corliss engine in the collection in order to pay homage to those early generating units.

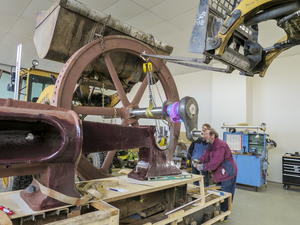

In 2017 our wish was fulfilled when the Reynolds Alberta Museum donated a surplus Corliss engine and ammonia compressor to our foundation. The crankshaft had been cut with a torch to make it more portable, and it had seen hard use in its 100 plus year life, evidenced by numerous scars and repairs (some better than others). But the flywheel was only 8 feet in diameter, making it ideal for installation in our museum, and upon delivery to our site, restoration activities began.

This engine was manufactured by the John Inglis Company of Toronto. Inglis is probably best known for the manufacture of home appliances from the immediate post war period until 2001.