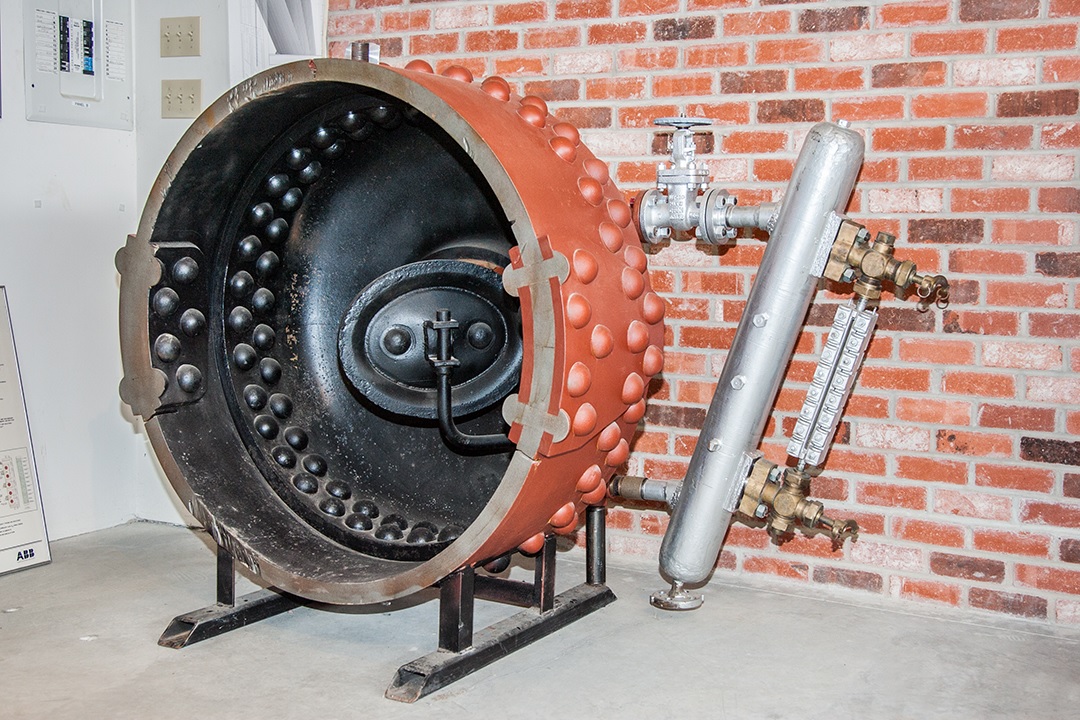

Riveted Steam Drum Head

1932

Pictured above is one head of a the steam drum from Boiler #2.

Each end of the Steam Drum is closed with a dished head. This was the last boiler that was made using riveted construction. The next drums used welded seams.

The man-way door provided access to the inside of the drum. This was useful during construction, for rolling in tubes, and during maintenance, cleaning and repairs.

The Steam Drum was located at the top of the boiler, about 40 feet off the floor. Pictured above is a steam drum from the first of seven Sterling boilers installed at the Rossdale Power Plant. These boilers operated at 400 psi.

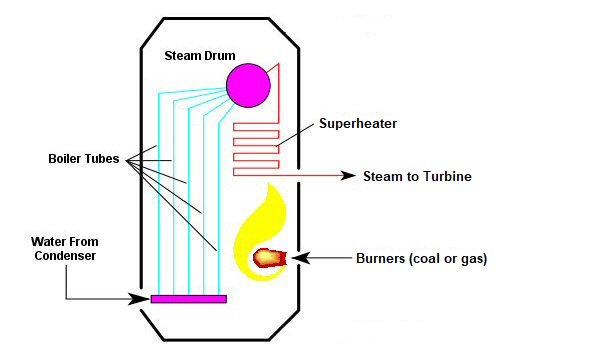

In the schematic below, the steam drum can be seen in magenta, collecting the hot steam from the boiler tubes, then sending the steam to the superheater for further heating before powering the turbine.

Specifications

Manufacturer: Babcock-Wilcox and Goldie McCulloch

Joint type: Double Riveted Double Butt Strap

Designation: Middle Steam Drum Head

Working pressure: 425 psi

Plate thickness: 1 13/16" (4.6 cm)

Tensile strength: 55,000 lb/sq. in.

Outside diameter: 48 inches (122 cm)

Rivet Diameter: 1 1/2" (3.8 cm)

Rivet Pitch: 4" (10 cm)

Manway opening: 12" x 16" (30 cm x by 40 cm)